Aluminum Composite Exterior Panel

Price 32 INR/ Square Foot

Aluminum Composite Exterior Panel Specification

- Protective Film

- Polyethylene removable film

- Feature

- Weather resistant, fire retardant, lightweight

- Usage

- Architectural, commercial, industrial

- Material

- Aluminum composite panel

- Dimension (L*W*H)

- 1220 mm x 2440 mm x 4 mm

- Surface Treatment

- PVDF coating

- Coating Thickness

- 25 micron PVDF coating

- Panel Thickness

- 4 mm

- Aluminum Thickness

- 0.50 mm

- Tensile Strength

- 50 MPa

- Yield Strength

- 45 MPa

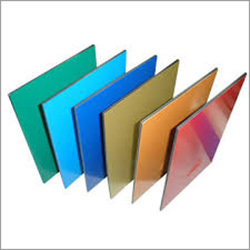

- Color

- Grey

- Application

- Exterior wall cladding, building facades

- Environmental Certification

- RoHS, SGS Compliant

- Finish

- Glossy, Matte, Brushed, Mirror

- Temperature Resistance

- -50°C to +80°C

- Core Material

- Non-toxic Polyethylene (PE) or Fire Retardant Core

- Weight

- 5.5 - 7.5 kg/m² (depending on thickness)

- Installation Method

- Rivet, Screw, Adhesive, Hanging system

- Fire Rating

- B1 or A2 Grade (optional as per request)

- Sound Insulation

- Excellent due to sandwich structure

Aluminum Composite Exterior Panel Trade Information

- Minimum Order Quantity

- 01 Square Foot

- Supply Ability

- 10000 Square Foots Per Day

- Delivery Time

- 10000 Days

About Aluminum Composite Exterior Panel

As the name suggests, our supplied Aluminum Composite Exterior Panel is widely used for installing in exterior of commercial buildings. It is designed by using fine grade aluminum that is procured from trusted vendors. Due to its accurate dimensions, it is easy o install and hence, highly demanded. Along with its elegant finish, it provides a sophisticated look to the buildings. Apart from this, Aluminum Composite Exterior Panel is checked on various quality parameters to ensure that it can withstand adverse weather conditions.

Features:

- Vibrant color

- Glossy finish

- Highly polished

Comprehensive Fire Safety Options

Select between B1 and A2 fire-rated panels to match your projects safety requirements. Fire retardant cores are available for enhanced protection, making these panels an excellent choice for buildings where fire safety is paramount. All options are engineered to meet stringent global standards.

Superior Weather and Impact Resistance

Each panel undergoes PVDF surface treatment for remarkable weather resistance, ensuring the facade remains visually striking and durable in harsh climates. With tensile strength 50 MPa and yield strength 45 MPa, these panels deliver reliable structural integrity alongside exceptional aesthetics.

Effortless Installation for Any Project

Designed for versatility, panels can be installed using rivets, screws, adhesives, or specialized hanging systems. This allows for efficient integration across building typesbe it commercial, industrial, or residentialwhile the lightweight nature streamlines logistics and labor requirements.

FAQs of Aluminum Composite Exterior Panel:

Q: How are aluminum composite exterior panels installed on buildings?

A: Aluminum composite exterior panels can be installed using rivets, screws, adhesives, or a hanging system. The choice of installation method depends on your specific project requirements, making these panels suitable for various wall structures and design needs.Q: What fire rating options are available for the panels?

A: Panels are available with B1 (standard fire retardant) or A2 (higher fire resistance, optional upon request) grades. You may request the appropriate fire rating depending on your buildings safety requirements.Q: When is it recommended to use a fire retardant core instead of a standard PE core?

A: A fire retardant core is recommended for applications in high-occupancy or high-risk buildings to meet stricter fire safety regulations. Standard PE core panels are suitable for environments with lower fire safety requirements.Q: Where can these panels be applied?

A: These panels are ideal for exterior wall cladding on commercial, architectural, and industrial buildings. Their durability and weather resistance make them particularly suitable for facades exposed to harsh outdoor conditions.Q: What is the benefit of the panels PVDF coating finish?

A: The 25 micron PVDF coating provides excellent weather resistance, helping the panel surface maintain its color and gloss for years. This coating also protects against pollutants and UV damage, ensuring a longer lifespan for your buildings facade.Q: How does the sandwich structure contribute to sound insulation?

A: The composite sandwich structure of the panel significantly enhances sound insulation, making it effective at reducing noise transmission. This feature is especially beneficial in busy urban or industrial environments.Q: What environmental certifications do the panels hold?

A: These panels comply with RoHS and SGS standards, signifying they are manufactured without hazardous substances, ensuring both environmental responsibility and safety for installers and occupants.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminum Composite Panels Category

Pet Laminated Aluminum Composite Panels

Price 32 INR / Square Foot

Minimum Order Quantity : 01 Square Foot

Color : Available in multiple colors, glossy/matte/wooden/marble/solid

Material : Other, Aluminum composite panel with PET film

Aluminum Thickness : 0.10 mm 0.50 mm (per side)

Coating Thickness : 25 micron (PET film) approx.

Aluminum Composite Interior Panel

Price 32 INR / Square Foot

Minimum Order Quantity : 01 Square Foot

Color : White, Silver, Grey, Custom Available

Material : Other, Aluminum Composite

Aluminum Thickness : 0.21 mm

Coating Thickness : 1825 Micron

Aluminum Composite Panels

Price 32 INR / Square Foot

Minimum Order Quantity : 01 Square Foot

Color : Multiple Colors Available

Material : Other, Aluminum Composite

Aluminum Thickness : 0.50 mm

Coating Thickness : 25 micron

Aluminum Partition Panel

Price 32 INR / Square Foot

Minimum Order Quantity : 01 Square Foot

Color : Silver, White, Customized

Material : Aluminum

Aluminum Thickness : 0.8mm

Coating Thickness : 1830 microns

|

|

SHREE UDYOG

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry